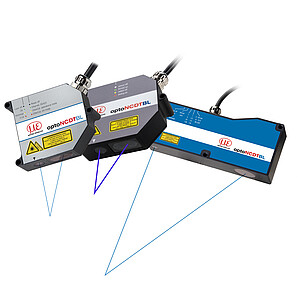

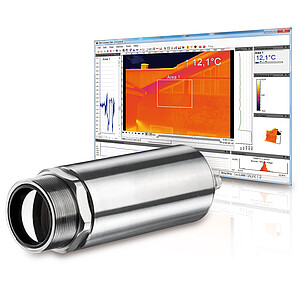

Battery production: 3D inline testing of binding posts

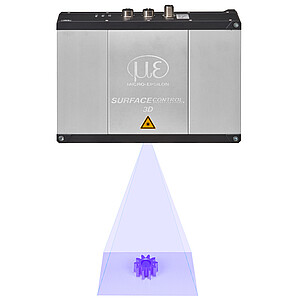

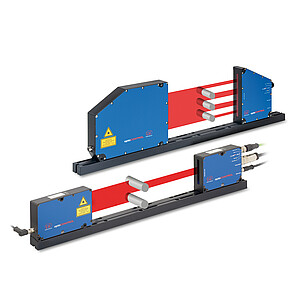

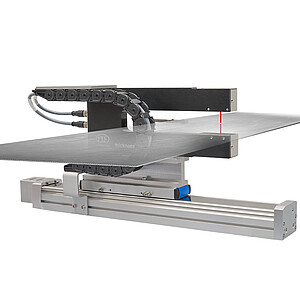

Precise measurement of the terminals is of crucial importance in the production of batteries. After the binding post, shunt and bridge have been welded, the coplanarity of these three components is checked using the surfaceCONTROL 3500-80 3D snapshot sensor.

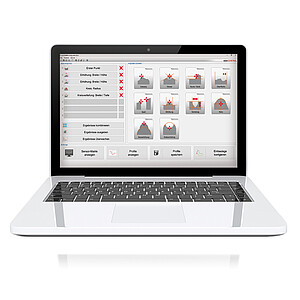

The surfaceCONTROL 3500-80 is integrated directly into the production line on the rotary indexing table. The sensor, which is positioned orthogonally to the target, generates a precise 3D point cloud within milliseconds. These data are transmitted via a Gigabit Ethernet interface to the customer's own software (Viper Vision from Gefasoft) and processed. Afterwards, the coplanarity is calculated.

The sensor offers particularly high data quality and therefore ensures precise results. Due to its compact design with inline capability, no additional controller is required, which saves space and money. In addition, the large field of vision of 80 mm x 50 mm allows for efficient measurement.