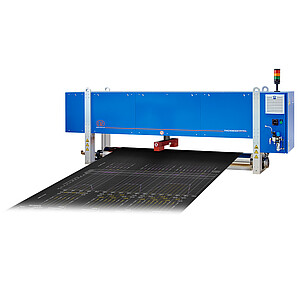

Monitoring the vertical alignment of high-bay racks

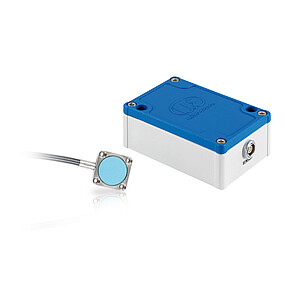

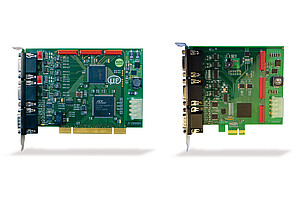

Fully automated high-bay warehouses often take on enormous dimensions. Lengths of around 80 m and heights of around 50 m can be achieved. Precise alignment of the racks is crucial for the fully automatic supply and removal of the stored goods. These high-bay racks must be precisely positioned vertically, as even small deviations can change the distances to the automated transport systems and therefore cause errors in the storage and retrieval process. For this reason, INC5701 inclination sensors are used, which permanently monitor the stability of the racks in the upper third. Movements and deviations are detected at an early stage and prevent the stored goods from jamming or even falling down.The INC5701 inclination sensors are connected to the control system or a PC via analogue output signals (current and voltage signal) or as RS485 network in combination with the Industrial Ethernet interface modules IF1032 (Ethernet) and IF2030 (PROFINET).